Sealed Grow Room Basics: What Growers Should Know?

Sealed grow rooms have gained massive popularity in the growers’ community, and expert growers prefer it to get optimal and fast growth. Together with LED grow lights, it can take indoor growing to the next level, which is why it has got a massive hype.

Beginners usually get confused when they hear the phrase “Sealed Grow Room”, and if you are one of them, you are in the right place.

Here, we will discuss everything about the sealed grow room setup, basics, pros & cons, air exchange, and everything you should know about it.

Let’s start the discussion without further delay.

- Part 1: What is a Sealed Grow Room?

- Part 2: Pros and Cons of Sealing Grow Room

- Part 3: How to Build a Sealed Grow Room?

- Part 4: How to Cool a Sealed Grow Room?

What is a Sealed Grow Room?

A sealed grow room is an advanced version of the grow room that enables you to control the environmental conditions and make them according to the needs of the plants.

It is a closed-loop system that is completely sealed and has no contact with the outer environment. The environmental factors are controlled inside the room to ensure optimal conditions.

Image Source: monstergardens.com

We call sealed grow rooms an advanced version because this is what experienced growers adopt to control the internal environmental conditions of the grow room. It requires temperature control, humidity control, CO2 control, and a few other factors to obtain the optimal condition that is favorable for indoor plants.

You might have seen grow tents and simply grow rooms. These grow rooms are open-loop or ventilated systems. It means they are connected with the outer environment in various ways.

Open-loop systems usually have an intake fan or hole to take the air. This inlet takes the air from the outside and replaces the air inside the grow room. The outside air has a different temperature and humidity that disturbs the environmental conditions of the grow room.

In an open-loop system, it is hard to control the environmental conditions because when you take the air from the outside, the environmental conditions are changed. Therefore, experts and commercial growers prefer a sealed grow room instead of the conventional open-loop grow room.

Another reason for calling a sealed grow room the advanced version is that the grower needs extra equipment and things to control the environmental conditions. There is a need to control the internal temperature, humidity, and CO2 concentration.

For all these environmental controls, the grower has to pay extra money which increases the overall cost of the grow room.

Simply put, if we consider a sealed grow room vs a vented grow room in terms of cost, then the cost of a sealed grow room will be much higher.

Pros and Cons of Sealing Grow Room

Like everything, sealed grow rooms also have some pros and cons. In this part, we will discuss the sealed grow room pros and cons in detail.

Pros:

Temperature Control

The first benefit of a sealed grow room is the control of the temperature. You can control the temperature inside using an air conditioner or heater. It ensures the right temperature that ensures optimal growth.

In a normal grow room, it is not easy to control the temperature. The air coming from the outside of the room is not of the same temperature you need. The outside temperature could be higher or lower.

If you want to maintain a temperature of 25 degrees and the temperature outside is too high, you need to use an air conditioner. You might think that the air conditioner can solve the problem, but this is not the case. The air conditioner will try to maintain the temperature, but the incoming air will always disturb the inside temperature.

Thus, the incoming air is a problem. This is the reason a sealed grow room has no inlet to take the air in.

Humidity Control

Humidity control is quite important if you want to ensure optimal growth. Too high and too low humidity are both dangerous to the plants.

Therefore, it is necessary to maintain the humidity according to the requirements of the plants. In an open-loop grow room, you can use a humidifier or dehumidifier, but again, the air coming into the grow room will keep disturbing the humidity.

In contrast, the humidifier and dehumidifier work well in a closed-loop system and ensure the right humidity in the area.

Optimal Growth and Yield

Plants need CO2 to carry out photosynthesis. Without CO2, the plants will not have the food/energy to survive. Therefore, the right amount of CO2 must be present in the air to ensure the proper growth of plants.

In normal grow rooms, the air is constantly replaced. So, you cannot increase the concentration of CO2 through supplementation.

In sealed grow rooms, you can supplement CO2 and keep the concentration high. It will eventually increase the growth rate of plants and overall yield.

VPD Control

VPD plays a very important role in indoor grow rooms. It stands for Vapor Pressure Deficit. It is the difference between the moisture in the air present at the moment and the maximum value of moisture in the air.

It is an important metric that helps you to ensure your plants are growing well. Expert growers take VPD very carefully to have rapid growth in plants.

Plants give off water through transpiration. They give off most of the water, more than 90% of what you give to them. Through transpiration, they create a space inside to absorb more water from the roots along with the nutrients.

Image Source: onlinelibrary.wiley.com

Without transpiration, there won’t be any space for nutrients, and plants will suffer from a shortage of food.

Thus, it is quite important to keep the transpiration process in its optimal state. High and low transpiration is not good for plants.

The transpiration of plants depends on the current content of moisture in the area. They transpire more if the VPD is high, and they transpire less if the VPD is low.

The plants react according to the VPD. If the VPD is too high, then the plants will transpire more. Consequently, their stomata will be open for a long time, and they will be absorbing more nutrients. Excess of nutrients in plants is not good, and it can cause toxicity.

If the VPD is too low, then plants won’t be able to transpire, and nutrients will be deficient.

Simply put, the control of VPD is quite important, and it is not easy in an open-loop system.

A sealed grow room or closed-loop system has the advantage of maintaining the VPD. The grower can control it and ensure the optimal growth of plants.

No Mildew

Because of high humidity, there are chances of mildew. It is quite dangerous and can ruin all your efforts. Controlling humidity is the utmost priority of an indoor grower.

Unfortunately, the humidity cannot be controlled easily inside an open-loop or ventilated grow room. The constant air circulation brings abrupt changes that affect the humidity level. Therefore, there are chances of mildew.

On the other hand, the sealed grow room allows you to control the humidity as needed. You can maintain any value to prevent the growth of microorganisms. Humidifiers and dehumidifiers work pretty well, and optimal humidity is ensured.

Cons:

High Cost

One of the major sealed grow room problems is their high cost. When you disconnect the grow room from the outer environment, you need to control everything and cater to the deficiencies. For that, you need extra equipment that increases the cost.

First, you need to create a sealed or airtight grow room. There is no entrance for air and light. You need to seal every hole or minimal space. For all that, you need to spend on various things, such as silicone, pest blocker, door seal, and window stickers.

For temperature control, you need an air conditioner or heater, depending on the temperature of the area where your grow room is.

For humidity control, you need a humidifier or dehumidifier. Moreover, CO2 supplementation is also necessary for the photosynthesis and optimal growth of plants.

You need these things, and obviously, they come at an extra cost.

Extra Care

Sealed grow rooms also need extra care. You need to monitor everything to maintain it accordingly.

For instance, you need to monitor the CO2 left in the cylinder. If there is no CO2 in the room, the plants won’t be able to synthesize their food. A sealed grow room without CO2 is dangerous for plants. So, you need to keep an eye on the cylinder and replace it when needed.

You need to be extra careful to keep the conditions in the optimal state.

Leakage and Draughts

A sealed grow room must be sealed from every corner. You need to seal every hole or place from where the air can enter or escape.

Sometimes, a few holes or places are left, or they might get open after some time. Therefore, you also need to take care of the leakages and draughts and make sure everything is perfect.

How to Build a Sealed Grow Room?

Setting up or building a sealed grow room is not that difficult. If you know the right steps and how to do it properly, you can do everything on your own. Let’s see what you need to do step-by-step.

Step 1: Choose an Area

The whole process starts with choosing an area. You need a suitable area for your sealed grow room. You cannot go for grow tent kits, and there is a separate dedicated space needed. You can choose your basement or a small room in your house.

While selecting the area, you need to take care of a few things that are listed below,

- Size of the grow room

- Flooring

- Water and electricity

The size of the grow room needs to be according to your requirements. If you want to grow commercially, you need a large space. If you are new to a sealed grow room and want to try it out, you can start with a small space.

The flooring of the area also matters. It is better to take care of flooring before creating a grow room. Inside a grow room, you will need to water the plants, and there will be moisture.

Thus, you need to ensure there is a proper drainage system, and the water can easily be drained and cleaned from the floor. Concrete floors are preferred as they do not absorb water, and it is easy to clean them.

Water and electricity are the next main considerations. There should be water outlets in your grow area if it is large. You can install all the required equipment, such as water pumps and hoses.

Growers need to take care of the electricity as well. They need to ensure safety. They will be using UV grow lights, so there should be outlets at the required places. Their wiring and electrical safety must be according to the fixtures you are going to install. It is better to contact a certified electrician to make sure everything is up to the standards.

After selecting the area, it is good to have a sealed grow room design. You can plan the placement of lights, air conditioning systems, pots, and other things.

Step 2: Seal Your Grow Room

Now, you need to seal your grow room. When the area is empty, you can seal it easily. First, you need to fill bigger holes in the area. Seal them using a concrete, wood plank, or expanding foam. The best way is to use expanding foam and seal all the holes and places.

The next thing you need to do is seal small gaps using silicone. You can seal the walls, ceiling, flooring, and everything where you see gaps.

Now, it is the turn to seal the doors. The sides of the doors are the reasons for passing the air. You need to seal them using gaskets. Finally, you need to seal the space under the door. You can use an underdoor seal or anything else you find feasible.

If you are unable to find the draughts in your grow room, you should try the candle trick. Light a candle and move it around the places of the air passage. The flame of the candle will be disturbed if there are any draughts.

You also need to seal the windows and places from where sunlight can enter. Use stickers to cover the window glass.

After sealing the grow area, your initial sealed grow room is ready.

Step 3: Indoor Grow Lights

Grow lights play the utmost important role in grow rooms. Without grow lights, a grow room is incomplete.

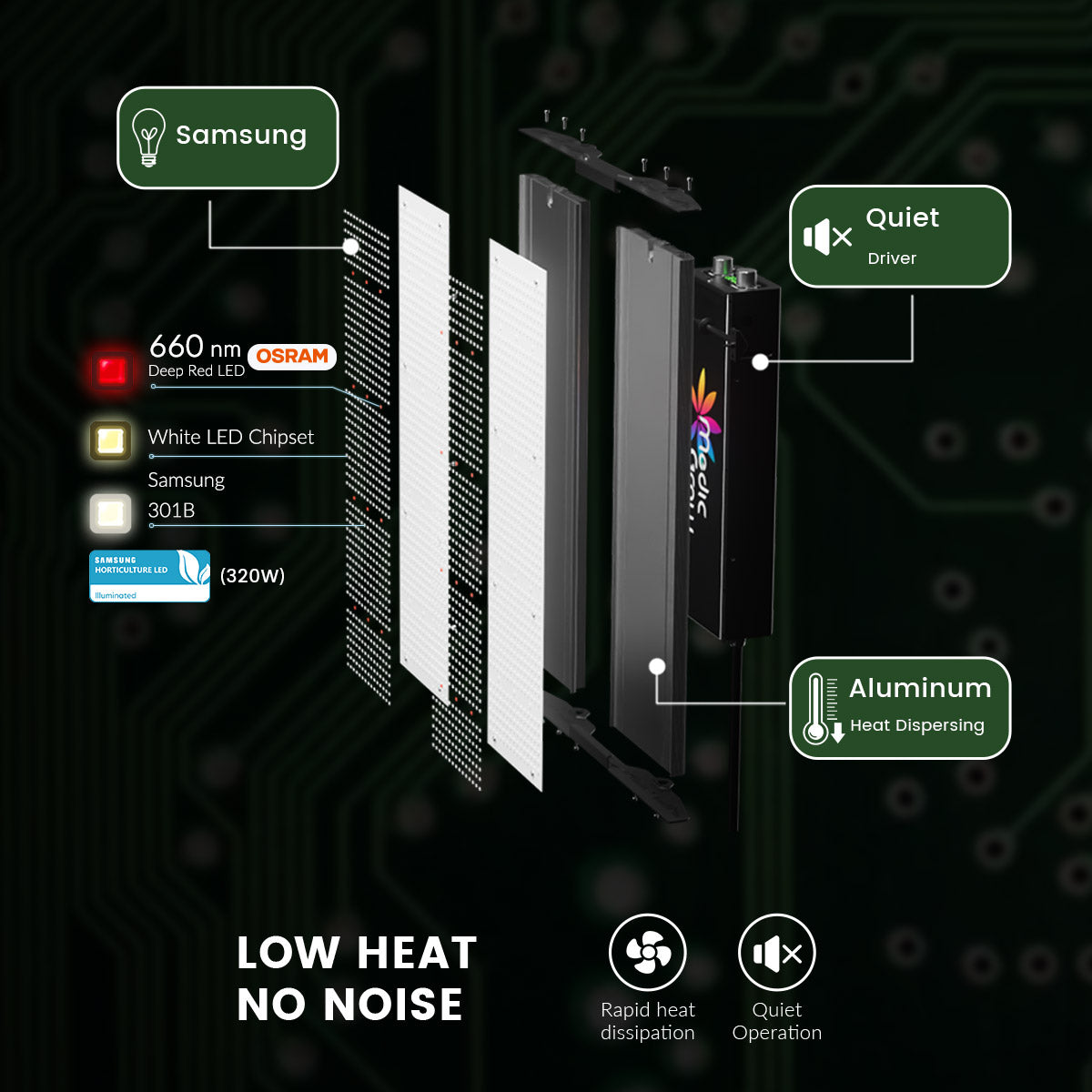

Grow lights, such as 800w LED grow light, mimic the sunlight and provide the radiation that plants need for photosynthesis. You need to select suitable lights for your sealed grow room.

There are various types of full-spectrum grow lights available in the market. Incandescent lamps, fluorescent lamps, and HIDs are not suitable for a sealed grow room as they emit too much heat, and your air conditioning system will have to work more than expected. Consequently, the electricity cost will increase.

The 1000W LED grow lights are suitable for sealed grow rooms. These are highly efficient, so there is minimal heat. Moreover, these save energy and have a great life span.

There are tons of benefits to using LED grow lights, and the most important of them is the control that you have. You can easily adjust the brightness and spectrum to make everything according to the needs of the plants.

LED grow lights, such as Medicgrow Spectrum X, have different spectrums that can be adjusted according to the growth stage of the plants. There is also a knob to adjust the brightness level.

Step 4: Set Up Air Conditioning and Heating

There is no exchange of air inside the room, so you can easily control the temperature. For that, there is a need for an air conditioning unit and a heater. It depends on the area where you live.

If the temperature is low, you need a heater, and if the temperature is quite high, you need an air conditioner. You might need both in some cases.

Install the air conditioner properly. It is better to have a split AC system as it is compact, and there are fewer chances of air leakage.

Installing a heater is not a big deal; you can even buy a portable heater for the purpose.

Step 5: Set Up Humidity Control

For humidity control, a humidifier and dehumidifier are needed. It is quite easy to use them inside a grow room.

You can use a hygrometer to monitor the humidity of your sealed grow room. If the humidity is low, you can use the humidifier, and if the humidity is high, you can use the dehumidifier.

Step 6: Set Up CO2 Supplementation

CO2 supplementation is needed for a sealed grow room. For this, there can be a CO2 generator or CO2 supplementary cylinder. Anything can be arranged to ensure the optimal CO2 level in the room.

How to Cool a Sealed Grow Room?

You might find several ways to cool your grow room. Those are using a venting duct, inline fans on the lights, water-chilled lights, and an air conditioning system.

All the above cooling methods have some drawbacks, except the air conditioning system, and they are not suitable for a sealed grow room.

The venting duct system connects the sealed grow room to the outer world; it is a way to ensure sealed grow room air exchange. But it ruins all the effort for creating the room by exchanging the air and disturbing environmental conditions.

Inline fans on lights work well, but they are not enough for the room. They cannot play a major part in controlling the sealed grow room temperature.

The water-chilled lights are a good way, but they increase the humidity in the area.

Air conditioning is the perfect method to cool a sealed grow room. It maintains the temperature automatically once you set the required temperature. There are commercial as well as mini air conditioning systems available according to the needs.

Although air conditioning systems require a big investment, it is worth it. It is a better way, and you will get excellent results.

Related Posts

How to Choose the Right Grow Fan for Your Grow Room/Tent

Learn About the Importance of Air Circulation for Indoor Plants

How To Control Humidity In Your Grow Tent?

Featured Products

Blog Posts

Contact Us with Any Idea!

- Choosing a selection results in a full page refresh.

!